Industrial environment. From design to installation.

OrderAbout us

RIOMTEQ – professional engineering company, supplier of equipment, systems and technological solutions in the field of waste paper processing, pulp and paper production.

Our offer

Our company offers services for the creation of technological systems of any complexity, carrying out pulp processing and paper production.

We сommitted to the research and development, promotion and application of special automation products and technologies, frequency drive systems, DCS, MMC, QCS, rewinder and rewind systems in the pulp and paper industry.

We integrate innovation and experience.

RIOMTEQ's experienced specialists, based on advanced equipment, implement various industrial facilities on a turnkey basis – from individual production lines to large-scale automated closed-cycle production enterprises.

Many years we design, control, and provide supervision services for erection, commissioning and Start-up of the paper machines. Our quality products and services are highly recognized by customers from many countries

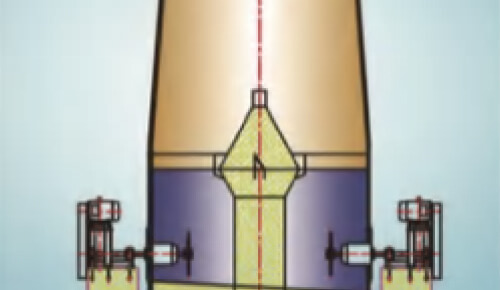

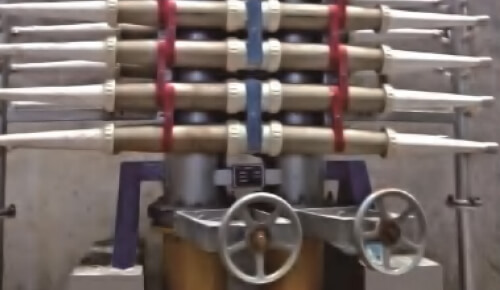

Main Equipment

Statistics

According to statistics, the production of fluff pulp is growing by about 4% annually, and according to forecasts, the growth of its production from 2017 to 2027 will grow from 5.8 to 8.5 air-dried tonnes.

At the same time, in May 2024 alone, the export price of bleached sulphate pulp from the European Union increased by 7%.

The global price of pulp also demonstrates stable annual growth due to the constant growth in demand for these products.

Our benefits

Turnkey engineering services and technical solutions.

We provide comprehensive services for technical design, delivery, installation at the customer's site, maintenance and repair of the entire range of equipment.

A wide range of manufacturing equipment.

The development of the complex is carried out using a range of modern equipment for the efficient processing of various raw materials and pulp production.

Guaranteed quality.

All offered equipment is certified

and meets international.

Supplies of spare and wear parts.

We supply our customers with spare and wear parts in day-to-day business: suction rolls, press rolls, guide rolls etc. Some parts could be custome manufactured on the base of existing drawings.

High level of manufacturing automation.

Professional equipment setup will allow the customer to save on the number and qualification of personnel.

High performance.

The company's specialists will calculate for you the performance of any industrial complex designed for specific tasks or for a clear budget.

Cost-effective operation.

The use of RIOMTEQ equipment will reduce energy consumption by an average of 40% per tonne of pulp.

Environmentally friendly production process.

With RIOMTEQ equipment, it is possible to obtain high-quality pulp from straw and other raw materials (including waste paper with the removal of printing ink).

Possibility of using new sources of raw materials for processing.

Large suppliers of waste paper, agro-industrial complex (straw), logging and woodworking production can act in this capacity.

Stages of interaction with customers

- Consultation on the project, discussion of terms and costs, preparation of project estimates

- Creation of technical specifications and signing of a contract with the customer

- Selection of a set of equipment

- Engineering and technical preparation of construction

- Issuance and approval of technical documentation

- Control of all stages of assembly of a production facility

- Commissioning works

- Customer service training

- Equipment testing